Products DescriptionStrong strength —— more than ten years of automatic Slack Adjuster domestic supply, exported to Southeast Asia, Europe, America and other regions, rich industry experience.Long service life —— surface galvanized treatment, strong rust resistance, prolong the service life of products.The use of global superior forging technology, to create a excessive energy adjusting arm, sturdy performance, now not handy to deformation.Sturdy and durable, appropriate anastomosis, whole product variety, quick transport time.Greater than ten years of home supply, exported to S

Hubungi sekarang

Products DescriptionSpecial trailer ——strong and durable, Slack Adjuster good anastomosis, complete product variety, short delivery time.Long service ——life strong performance, surface galvanized treatment, strong rust resistance, prolong the service life of products.Sturdy and durable, exact anastomosis, entire product variety, quick shipping time.The use of global superior forging technology, to create a excessive power adjusting arm, robust performance, now not convenient to deformation.Greater than ten years of home supply, exported to Southeast Asia, Europe, America and dif

Hubungi sekarang

Products DescriptionThe 3500 lb trailer axle sold by DARO has the advantages of high efficiency, environmental protection, energy saving, safety, reliability, convenience, etc. It will not produce waste gas and noise, and can reduce environmental pollution.

Hubungi sekarang

Products DescriptionTrailer axle brake Slack Adjuster is produced by a strong supplier and has been supplied domestically for more than ten years. It is exported to Southeast Asia, Europe, the Americas, and other regions with rich industry experience. The surface has been galvanized, with strong rust resistance, extended product service life, high precision, high strength, and suitable for trailer use.The Trailer axle brake Slack Adjuster belongs to the manual adjustment arm, which is used to manually adjust the brake clearance.

Hubungi sekarang

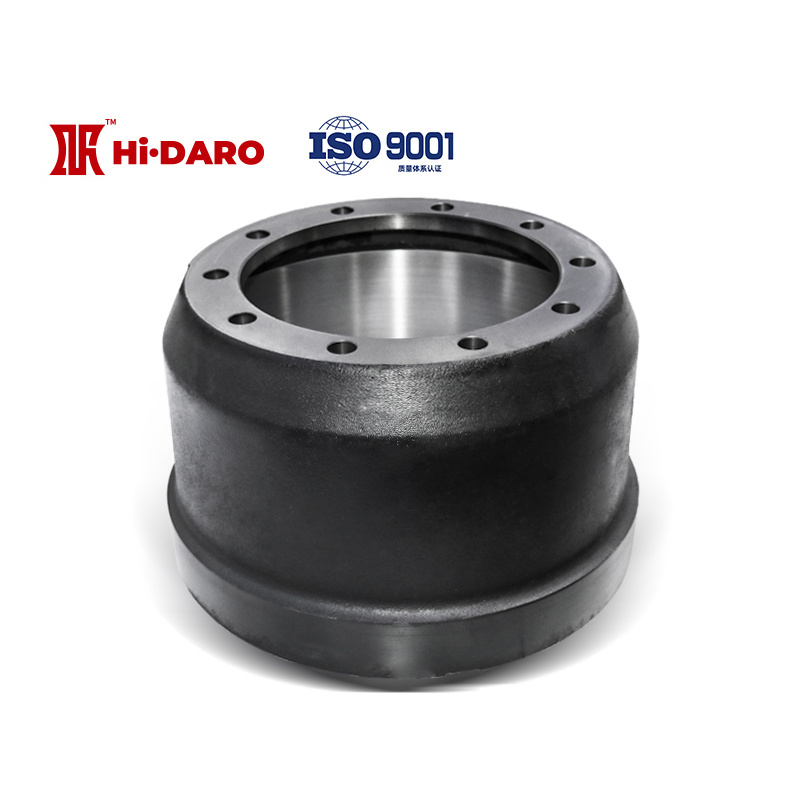

Products DescriptionDARO Group produced and sold the commercial trailer axles brake drum with reinforcement design, which not only can improve the strength of the brake drum, prevent deformation and cracking, but also can improve the efficiency of air flow during high-speed driving, enhance the heat dissipation function, and prevent the wheel end from overheating. DADO galvanized trailer axle axle head adopts German design, small diameter, light weight, more stable connection with bearings, hubs and other parts, which can ensure the long-term application of the axle.ModelMax.

Hubungi sekarang

Products Description8000lbs trailer axle,is a classic light trailer rear axle that adopts a single tire design to reduce its own weight, simplify maintenance procedures, simplify replacement, reduce user downtime, improve operational efficiency, and improve strength and toughness. Safety performance such as rigidity, wear resistance, and fatigue resistance strictly meet the standards.ModelMax.

Hubungi sekarang

Products DescriptionDARO 12T square trailer axle adopts German type axle head design with complex shape and smaller diameter width, which can effectively reduce its own weight, improve vehicle loading space compliance, and enhance the connection stability between the axle head and the bearing to maintain good heat dissipation under high-speed operation. There is no overheating aging phenomenon.

Hubungi sekarang

Products DescriptionDARO 3tons agricultural trailer axle features lighter and more compact shape, higher stiffness and accuracy, high production and processing accuracy, and can maintain good sealing under high-speed operation, maintain internal cleaning of components, maintain operation safety and extend service life. Finished product online testing + manual quality inspection + limit test, the quality is strictly in line with industry standards.ModelMax.

Hubungi sekarang

Products Description72 inch spring center trailer axle is a classic American axle suitable for all types of American axles. High strength seamless steel pipes are selected with excellent production technology. Adding a medium frequency quenching strengthening process makes the shaft head stronger, stronger, and more durable.ModelMax.

Hubungi sekarang

Products DescriptionHigh-quality 6T trailer axle supply specially for trailer axle has gone through more than ten professional production processes, automatic production line setting, reliable and guaranteed production precision, and finished products online detection + manual quality inspection + extreme limit test to ensure that the quality strictly conforms to the industry standards. Flexible configuration and parameters can be changed according to customer requirements, customized production, to meet the differentiated needs of customers.ModelMax.

Hubungi sekarang

Products Description1ton trailer axle assembly selects 20Mn2 high-strength alloy seamless steel pipe as the raw material, and goes through 15 processes to create it with ingenuity.

Hubungi sekarang

Products DescriptionAirbag trailer axle uses airbags instead of traditional leaf spring structures, which are lighter in weight and beneficial for reducing vehicle weight, saving fuel consumption.

Hubungi sekarang

Products DescriptionUnderslung trailer axle,It can be matched with different widths/thicknesses/pieces, and the number of leaf springs can be freely selected according to the load. The raw material is made of silicon manganese spring steel, which has a long service life and high load.

Hubungi sekarang

Products DescriptionDouble axle tilt trailer axle Using 20Mn2 excessive electricity alloy seamless metal pipe, product fantastic is greater reliable.Strong bearing capacity, to make sure the long-term environment friendly operation of vehicles.With more desirable bending and torsional resistance, no bending and deformation below excessive strength.ModelMax.

Hubungi sekarang

Products DescriptionThe tonnage of DARO German type Trailer axle Beam ranges from 11 tons to 20 tons, and can also be customized according to customer needs. The 150*150mm square axle tube has large section coefficient, strong torsional and bending resistance, easy to bend, and more reasonable bearing capacity. Integrated hot rolling process, improve the overall mechanical performance of the axle, the specially designed shape of the shaft head, good match with the bearing, excellent lubrication effect, less resistance, to ensure long-term efficient operation of the vehicle.ModelMax.

Hubungi sekarang

Products DescriptionAmerican Style quality trailer products axle,adopts a locally reinforced square axial beam design, with a large cross-sectional coefficient and strong torsional and flexural resistance. The overall heat treatment technology improves the overall mechanical performance of the axle and has good fatigue resistance and toughness.ModelMax.

Hubungi sekarang

Products DescriptionDARO trailer axle Brake Drum:Select raw materials -——Using lighter weight high-strength alloy raw materials to reduce product weight.Mature process -——heat treatment and tempering, better wear resistance, good fit with brake shoes, improve driving safety.Reliable quality —— faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection -——assembly line production, single inspection out of the warehouse, stable and reliable quality.DARO trailer axle Brake Drum is suitable for 13T-16T drum axle.

Hubungi sekarang

Products DescriptionThe DARO trailer axle with disc brake has a lighter weight, and the 360° brake drum is banned, which greatly improves the weight. At the same time, after the installation of the disc axle, there is no need to install the water sprinkling device, which can further increase the load of the vehicle.

Hubungi sekarang

Products DescriptionDisc brake trailer axles,developed and manufactured by Daro Group, the first vehicle bridge enterprise in the Liangshan Special Purpose Vehicle Production Base to mass produce integrated axles, the axle body and axle head are polished and formed on the same high-strength alloy steel pipe, which is superior to the welded axle head in terms of heavy load performance.

Hubungi sekarang

Products DescriptionAlthough the 3T new trailer axle has become smaller and lighter in appearance, its raw material is still high-strength 20Mn2 seamless steel pipe, so it can ensure the strength and stiffness of the axle while achieving light weight. At the same time, DARO 3T new trailer axle adopts more simplified maintenance process, easier replacement, reduces users' outage time, and improves operation efficiency.ModelMax.

Hubungi sekarang

Products DescriptionDARO trailer axle Camshaft features uniform force transmission, wear resistance and durability, selected high quality alloy raw materials, created by new technology, strong bearing capacity and stable use. The transmission effect is better, which can effectively meet the needs of large transmission torque, and the practical effect is better.

Hubungi sekarang

Products DescriptionThe 5200lbs electric trailer axle designed and produced by DARO Group is compact in structure, cost-effective and high in safety. An emergency switch is also set on the brake synchronizer to help the front car stop when the front brake fails.

Hubungi sekarang

Products DescriptionDARO American Style trailer axle adopts new optimized design, which is lighter in weight than traditional American axle and achieves lightweight without sacrificing strength. The product design fully conforms to industry standards, the accessories are universal, the maintenance is convenient, and the trailer has passed strict ultimate performance test, with strong environmental adaptability. Can adapt to complex use environment.ModelMax.

Hubungi sekarang

Products DescriptionShock absorption and buffering: Highly rigid and durable compact trailer axle adopts advanced shock absorption and buffering devices, which can effectively absorb and disperse the impact and vibration from the road, improving the comfort and safety of the vehicle.ModelMax.

Hubungi sekarang